Behind the Scenes: How Custronics LED Display Are Made

- Fievel Yap

- Apr 23, 2025

- 2 min read

Ever wondered how LED display comes to life? At Custronics, every display we produce is crafted with precision and care. In this behind-the-scenes look, we will walk you through the key stages of our manufacturing process - from concept to completion.

1. Design and Planning

Every great LED display begins with a clear plan. Our engineers and designers collaborate to understand the customer’s needs – regardless of size, resolution, viewing distance, brightness, and installation environment.

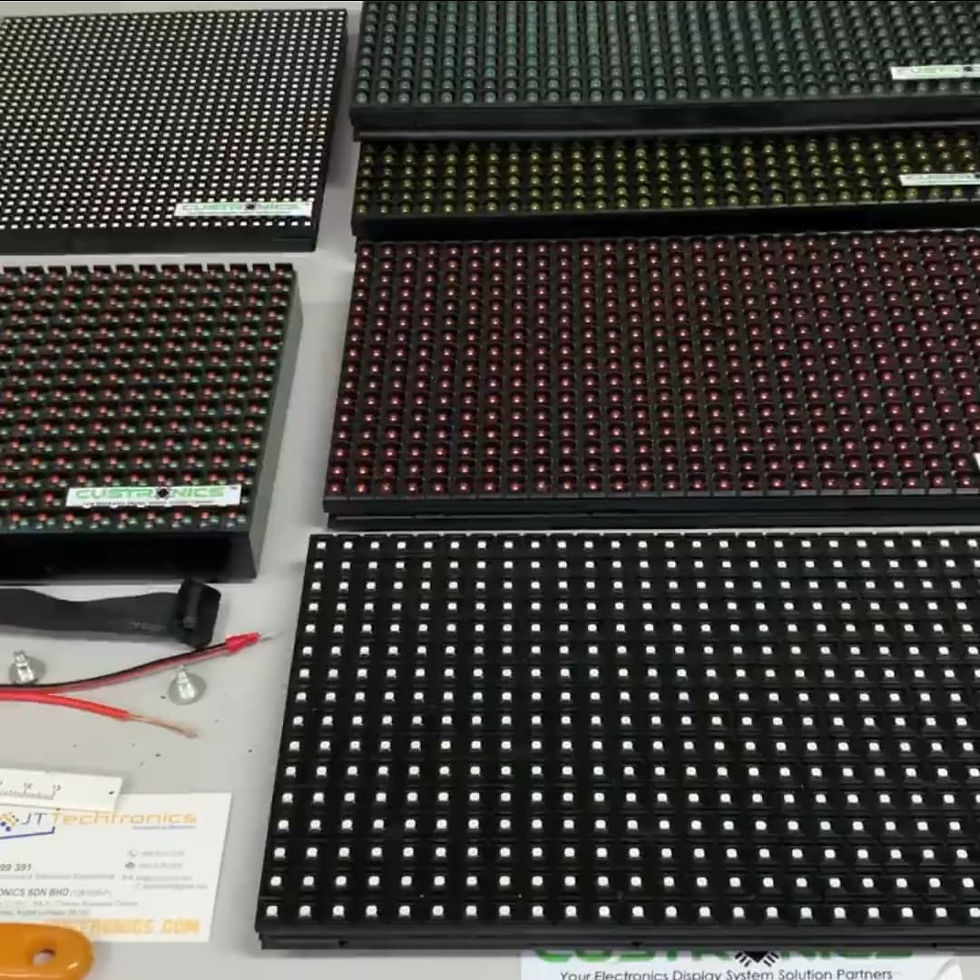

2. Component Selection

We source only high-quality components, including LED modules, drivers, control boards, and power supplies. Choosing reliable, durable parts is essential to ensure long-lasting performance, especially for outdoor and industrial environments.

3. PCB Assembly

Printed Circuit Boards (PCBs) are the backbone of any LED display. In our assembly process, LEDs and other components are placed on the board precisely. After that, we perform soldering and quality checks to ensure every connection is secure.

4. Module Testing and Calibration

Each LED module undergoes rigorous testing to check for brightness, color uniformity, refresh rate, and viewing angle. Calibration is critical. It ensures that your display looks vibrant, accurate, and consistent across the entire screen.

5. System Integration

Once the components and modules are ready, we assemble them together with the controller board that allows connectivity, and automation. Our displays can be customized for various applications - like production counter, safety scoreboard, weight remote display, queue management system, or sports event displays.

6. Final Inspection and Burn-In Test

Before delivery, every LED display goes through a comprehensive final inspection. We also run a burn-in test - keeping the display active for several hours to detect any early issues, ensuring it performs flawlessly out in the field.

7. Packaging and Delivery

Finally, the display is carefully packed using protective materials to avoid any damage during shipping. Whether it’s heading to a factory, condo, or airport terminal, we make sure it arrives in perfect condition, ready to install.

Why This Matters? By controlling every stage of the manufacturing process, Custronics delivers LED display products that are reliable, customizable, and built to last. Our clients get more than just a screen. They get a solution tailored to their needs, backed by expert support.

Visit www.custronics.com or contact us today to learn more about our display systems and custom solutions.

Comments