How Lean Six Sigma Improves Production Efficiency And Quality?

- Fievel Yap

- Apr 16, 2020

- 2 min read

What is six sigma?

Six sigma is a set of techniques and tools for process improvement, a data-driven problem-solving methodology. The goal is to have a continuous process improvement, by eliminating the defects to its lowest, closed to perfect, or 99.999% defect free.

How does it work?

There are five stages in this this approach; define, measure, analyze, improve and control. In short, it is a DMAIC framework.

· DEFINE – Define the problems and the objectives.

· MEASURE – What do we need to improve? Is this measureable?

· ANALYZE – Analyze the process. Define the factors of influence (the root cause).

· IMPROVE – Identify the final root causes and implement solutions to improve the process.

· CONTROL – Assure that improvements will sustain (process standardization in this phase).

What is the difference between lean production and six sigma?

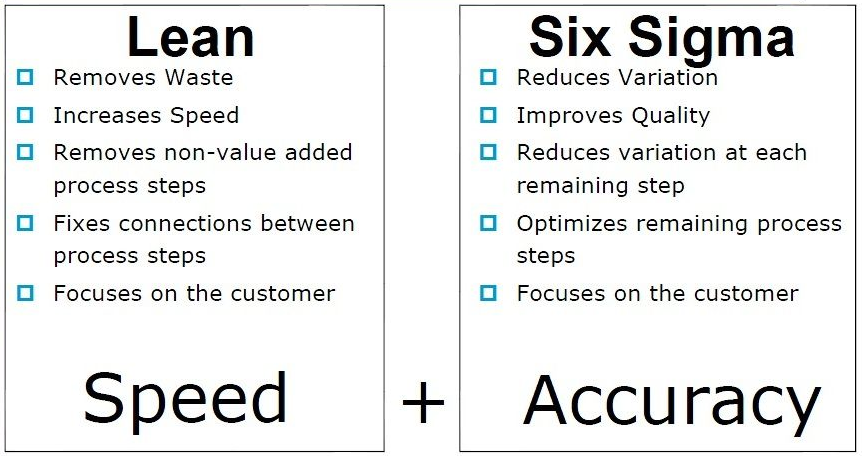

As mentioned in our previous blog (How Lean Production Reduce Cost), lean production is a systematic manufacturing approach that focuses on eliminating waste while increasing the value and reduces costs. Six sigma focuses on achieving consistent results with the most minimum defect. Essentially, both shares the same goal, which is to eliminate waste and creating the most efficient system possible. It is just that they have a different approach in achieving this goal.

Can we have both lean and six sigma together for the business?

Most people think you have to do one or the other: Lean OR Six Sigma - this isn’t the case. You simply cannot have one without the other in today’s dynamic environment.

When we combine lean and six sigma strategies together, one focuses on eliminating waste and reduce process complexity, while the other focuses on variation – reduction in process, the principles of Lean Six Sigma helps to improve the efficiency and quality of the process.

By the end of the day, with the combination of lean and six sigma, that gives you speed and accuracy, both approaches go hand in hand to provide you better delivery, better quality, employees’ satisfaction, and customer satisfaction.

JT Techtronics is one of the house production and manufacturer for the Andon system Custronics LED display panel, specializing in production counter for the industrial use.

With the variety products and system customization they have, feel free to contact JT Techtronics at https://www.custronics.com for more information, and the personnel-in-charge will follow-up with you to provide you a system that suits your production.

Comments